World Class Flexible Cable

Flexible Cables play a crucial role in powering and connecting various industrial systems and machinery. They are specifically designed to withstand demanding environments, high temperatures, and mechanical stress. ADCAB is a trusted manufacturer known for its extensive range of industrial cables. Their wires are reliable, durable, and ensure efficient electrical connectivity in industrial settings. For more information, you can visit ADCAB's official website and explore their comprehensive selection of Flexible Cables.

Starring Features

Governnment Certified

ADCAB cable is certified will all govt parameter including ISI CE ISO etc

100% Safe

ADCAB wires are 100% safe & shockproof for human as well as environemnt

Energy Saving

ADCAB wire always use superior quality insulation to prevent current leakage

MULTI STRANDED COPPER CONDUCTOR FR PVC INSULATED & ST-3 GRADE OUTER SHEATHED SINGLE CORE FLEXIBLE CABLE GRADE (UP TO 1100 V) - ADCAB Make

Application : Cable Suitable for internal wiring of control & instrumentation panels, motor Starters, relay, controllers, Connectors, Static etc,

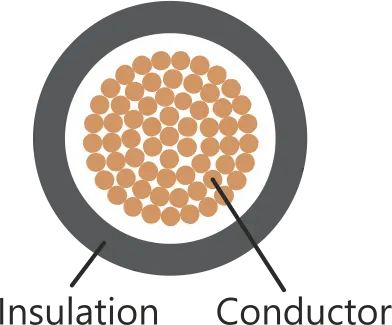

Construction Of Cable

BIS : IS 694:2010

Conductor : Electrolytic Grade Plain Annealed Copper as IS:81 30

Insulation : Primary - Natural PVC with FR Properties Secondary - Skin Color coated PVC with FR Properties

Voltage Grade : Up to and including 1100 V

Packing : Standard IW Mtr Coil. Longer Length in Wooden Drum

Color : Standard Black Color, Others - as per customer requirement

Construction Of Cable

BIS : IS 694-2010

Conductor : Electrolytic Grade Plain Copper Class V as per IS:8130

Insulation : Primary - Natural PVC with FRLS Properties Secondary - Skin Color Coated PVC with FRLS Properties

Voltage Grade : Up to and including 1100 V

Packing : Standard 100 mtr coil / 500 or 1000 Mtr. Wooden Drum

Cable Color : Standard Black Color. Others as per special request

Range : 0.5 sq mm to 1000 sq mm

Cable Technical Perameter

| Nominal Cross Sectional Area of Conductor (sq. mm) | Number Max. Dia. of Strands | Nominal Insulation Thickness (mm) | Approx Overall Diameter (Max) (mm) | *Current Carrying Capacity (AMPS) | Max. Conductor Resistance pr KM @ 20 C |

|---|---|---|---|---|---|

| 10 | 140/0.30 | 1.0 | 6.10 | 51 | 1.91 |

| 16 | 126/0.40 | 1.0 | 7.20 | 68 | 1.21 |

| 25 | 196/0.40 | 1.2 | 8.85 | 82 | 0.780 |

| 35 | 276/0.40 | 1.2 | 10.05 | 110 | 0.554 |

| 50 | 396/0.40 | 1.4 | 11.95 | 140 | 0.386 |

| 70 | 551/0.40 | 1.4 | 13.65 | 214 | 0.272 |

| 95 | 760/0.40 | 1.6 | 15.85 | 260 | 0.206 |

| 120 | 950/0.40 | 1.6 | 17.40 | 305 | 0.161 |

| 150 | 1180/0.40 | 1.8 | 19.35 | 355 | 0.129 |

| 185 | 1480/0.40 | 2.0 | 21.50 | 415 | 0.106 |

| 240 | 1880/0.40 | 2.2 | 24.40 | 500 | 0.0801 |

| 300 | 2360/0.40 | 2.4 | 27.30 | 570 | 0.0641 |

| 400 | 3085/0.40 | 2.6 | 31.15 | 690 | 0.0486 |

Multistranded Copper Conductor Frls Pvc Insulated & St-3 Grade Outer Sheathed Multi Core Flexible Cable Voltage Grade Up To 1100 V - Adcab Make

Application :Cable Suitable for internal wiring of all type of Industrial, Residential & Commercial, Infrastructure, Machineries, Tools for Controlling & Instrumentation, Motors etc

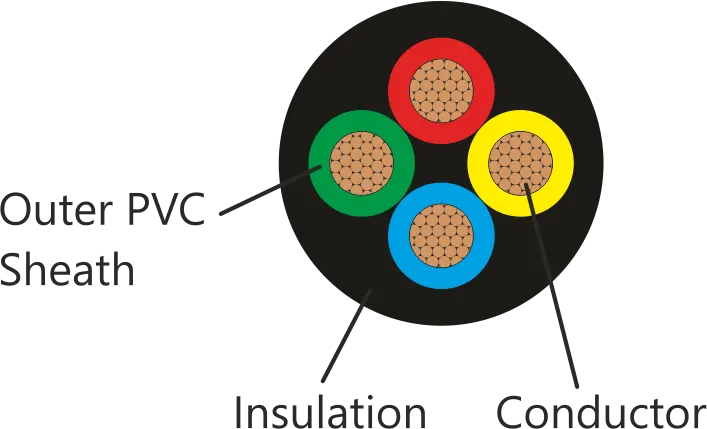

Construction Of Cable

BIS : IS 694:2010

Conductor : Electrolytic Grade Plain Annealed Copper Class V as per IS:8130

Insulation : Type D, FRLS PVC Compound

Sheath : Flexible Grade PVC

Voltage Grade : Up to and including 1100 V

Packing : Standard 100 Mtr Coil. Longer in Wooden Drum as per customer requirement

Cable Color : Black, Gray & White, Others - as per customer requirement

Range :0.5 sq mm to 1000 sq mm in Single Core

0.5 sq mm to 400 sq mm in Multi Core

CORE IDENTIFICATION

2 CORE : Red, Black

3 CORE : Red, Black & Yellow-Green*

4 CORE : Red, Yellow, Blue Yellow-Green*

5 CORE : Red, Yellow, Blue, Black & Gray

6 CORE : Red, Yellow, Blue, Green, White & Yellow-Green

7 CORE : Numbering in Each Core / Color Coding as specified in IS:694 and above

| Nominal Cross Sectional Area of Conductor (sq. mm) | Number Max. Dia. of Strands | Nominal Insulation Thickness (mm) | Nominal Thickness of Sheath | Approx Overall Diameter | Max. Conductor Resistance per KM @ 20 C Ohms | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 Core mm | 6 Core mm | 7 Core mm | 8 Core mm | 10 Core mm | 5 Core mm | 6 Core mm | 7 Core mm | 8 Core mm | 10 Core mm | ||||

| 0.50 | 16/0.20 | 0.6 | 0.9 | 0.9 | 0.9 | 1.0 | 1.0 | 7.55 | 8.2 | 8.2 | 9.3 | 10.5 | 39.0 |

| 0.75 | 24/0.20 | 0.6 | 0.9 | 1.0 | 1.0 | 1.0 | 1.1 | 8.1 | 9.0 | 9.0 | 10.0 | 11.5 | 26.0 |

| 1.0 | 32/0.20 | 0.6 | 0.9 | 1.0 | 1.0 | 1.0 | 1.1 | 8.75 | 9.5 | 9.5 | 10.65 | 12.2 | 19.5 |

| 1.50 | 30/0.25 | 0.6 | 0.9 | 1.0 | 1.0 | 1.1 | 1.1 | 9.5 | 10.3 | 10.3 | 11.75 | 13.3 | 13.3 |

| 2.50 | 50/0.25 | 0.7 | 1.0 | 1.1 | 1.1 | 1.2 | 1.3 | 11.25 | 12.5 | 12.5 | 14.25 | 16.3 | 7.98 |

| Nominal Cross Sectional Area of Conductor (sq. mm) | Number Max. Dia. of Strands | Nominal Insulation Thickness (mm) | Nominal Thickness of Sheath | Approx Overall Diameter | Max. Conductor Resistance per KM @ 20 C Ohms | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 12 Core mm | 14 Core mm | 16 Core mm | 19 Core mm | 24 Core mm | 12 Core mm | 14 Core mm | 16 Core mm | 19 Core mm | 24 Core mm | ||||

| 0.50 | 16/0.20 | 0.6 | 1.0 | 1.1 | 1.1 | 1.1 | 1.2 | 10.85 | 11.55 | 12.2 | 12.8 | 15.15 | 39.0 |

| 0.75 | 24/0.20 | 0.6 | 1.1 | 1.1 | 1.2 | 1.2 | 1.3 | 11.85 | 12.45 | 13.30 | 13.30 | 16.5 | 26.0 |

| 1.00 | 32/0.20 | 0.6 | 1.1 | 1.1 | 1.2 | 1.3 | 1.4 | 12.6 | 13.25 | 14.15 | 14.15 | 17.8 | 19.5 |

| 1.50 | 30/0.25 | 0.6 | 1.1 | 1.2 | 1.2 | 1.3 | 1.4 | 13.75 | 14.6 | 15.45 | 15.45 | 19.4 | 13.3 |

| 2.50 | 50/0.25 | 0.7 | 1.3 | 1.3 | 1.4 | 1.4 | 1.5 | 16.9 | 17.75 | 18.95 | 18.95 | 13.6 | 7.98 |

| Nominal Cross Sectional Area of Conductor (sq. mm) | Number Max. Dia. of Strands | Nominal Insulation Thickness (mm) | Nominal Thickness of Sheath | Approx Overall Diameter | Current Rating AC | Voltage Drop / AMP. / MTR | Max. Conductor Resistance per KM @ 20 C Ohms | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 Core mm | 3 Core mm | 4 Core mm | 2 Core mm | 3 Core mm | 4 Core mm | DC Single Phase AC mV | 3 Phase AC mV | |||||

| 0.50 | 16/0.20 | 0.6 | 0.9 | 0.9 | 0.9 | 6.05 | 6.40 | 6.95 | 4 | 83 | 72 | 39.0 |

| 0.75 | 24/0.20 | 0.6 | 0.9 | 0.9 | 0.9 | 6.45 | 6.85 | 7.45 | 7 | 56 | 48 | 26.0 |

| 1.00 | 32/0.20 | 0.6 | 0.9 | 0.9 | 0.9 | 6.80 | 7.20 | 7.85 | 11 | 43 | 37 | 19.5 |

| 1.50 | 30/0.25 | 0.6 | 0.9 | 0.9 | 1.0 | 7.40 | 7.80 | 8.75 | 13 | 31 | 26 | 13.3 |

| 2.50 | 50/0.25 | 0.7 | 1.0 | 1.0 | 1.0 | 8.85 | 9.40 | 10.30 | 18 | 18 | 16 | 7.98 |

| 4.00 | 56/0.30 | 0.8 | 1.0 | 1.0 | 1.0 | 10.35 | 11.0 | 12.10 | 24 | 11 | 9.6 | 4.95 |

| 6.00 | 84/0.30 | 0.8 | 1.1 | 1.2 | 1.2 | 11.70 | 12.65 | 13.90 | 31 | 8 | 7 | 3.30 |

| 10 | 140/0.30 | 1.0 | 1.3 | 1.4 | 1.4 | 14.75 | 15.95 | 17.50 | 42 | 4 | 3.5 | 1.91 |

| 16 | 126/0.40 | 1.0 | 1.4 | 1.4 | 1.4 | 17.10 | 18.25 | 20.10 | 57 | 2.5 | 2.2 | 1.21 |

| 25 | 196/0.40 | 1.2 | 1.4 | 1.5 | 1.6 | 20.50 | 22.10 | 24.62 | 72 | 1.6 | 1.4 | 0.780 |

| 35 | 276/0.40 | 1.2 | 1.6 | 1.6 | 1.7 | 23.20 | 24.80 | 27.60 | 91 | 1.2 | 1.0 | 0.554 |

| 50 | 396/0.40 | 1.4 | 2.0 | 2.0 | 2.0 | 27.9 | 29.8 | 32.9 | 120 | 0.97 | 0.84 | 0.386 |

| 70 | 354/0.50 | 1.4 | 2.2 | 2.2 | 2.2 | 31.6 | 33.8 | 37.35 | 200 | 0.7 | 0.62 | 0.272 |

| 95 | 484/0.50 | 1.6 | 2.4 | 2.4 | 2.4 | 36.5 | 39.0 | 43.15 | 225 | 0.59 | 0.48 | 0.206 |

| 120 | 608/0.50 | 1.6 | 2.5 | 2.5 | 2.5 | 36.75 | 42.55 | 47.05 | 305 | 0.48 | 0.42 | 0.161 |

| 150 | 750/0.50 | 1.8 | - | 2.6 | 2.6 | - | 47.0 | 52.0 | 355 | - | - | 0.129 |

| 185 | 925/0.50 | 2.0 | - | 2.8 | 2.8 | - | 52.0 | 57.60 | 415 | - | - | 0.106 |

| 240 | 1210/0.50 | 2.2 | - | 3.0 | 3.0 | - | 58.7 | 65.0 | 500 | - | - | 0.0801 |

| 300 | 1527/0.50 | 2.4 | - | 3.2 | 3.2 | - | 65.30 | 72.40 | 587 | - | - | 0.0641 |

Get Best Price